Design Process of Laser Cut Name Plates

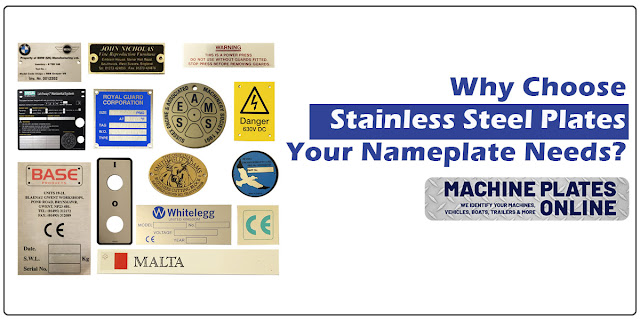

What is Laser Cut Names Plates? This is a process where the high-end printers utilize the excitation of laser light to cut out various shapes from metals. The basic materials that are used for the cutting process include steel, aluminum and sometimes brass, pewter or nickel. When it comes to choosing an appropriate name plate for your company’s control panel, there are some considerations to keep in mind. This article looks at some of these considerations in detail.

Design process of laser cut name plates is a customized process where different shape and sizes of metal sheets are used for cutting. After these plating sheets are cut, they are manually inverted in order to expose the copper layer. Copper layer acts as an insulator thereby making it hard for metal to conduct electricity. Design process of laser cut name plates uses a computer-assisted design program that controls the overall appearance of the plate by altering the color, pattern, surface texture, dielectric constant and thickness.

ALSO READ: What is the Importance of Serial Number plates?

The process of designing laser cut name plates is an interesting one. You could think that it would be the same as a regular name plate, but the design process requires some extra steps that aren’t always seen in ordinary name plates. This is because there are a few different types of these plating items, and they are made with slightly different processes. This article will look at the three main processes used to create laser-cut name plates.

These three processes can all be achieved in two ways, and each way does a pretty good job of creating unique laser cut nameplates. If you want a plate made to a certain shape and size, then you can always use the software package to design the plate for your needs. It is possible to scan in the information that you want on the plate into the program, and then it is up to the laser to cut the plate out exactly the way that you want it.

There are many advantages of using laser cut name plates. The first advantage is that this process provides flexibility to customers in choosing the designs and shapes as they need. Second, this method is fast, which is important especially in today’s competitive business environment. Third, using this method can produce higher quality output as the plate is manipulated in a precise manner.

This plate is produced through a computer controlled machine, which cuts the required amount of metal depending on the required thickness. The plate is then inverted and polished to achieve the final polish desired. This process produces the most durable and beautiful laser cut name plates at competitive prices. This particular equipment is made up of dual-sided plate which allows the plating process to be performed accurately and efficiently.

However, if you are looking to get a name plate that is already designed, then this process isn’t necessary. You can still design the plate, and then it will be done by the laser. This is a convenient way for most people to get what they want, but they have to be careful about being exact in their designs. The plates usually come out looking better when a little bit of space is allowed for the letters.

If you are interested in creating unique name plates or locker name plates for your business, you should consider our company Machine Plates Online. Contact us at (262) 369-5800 or visit our website here to schedule an appointment with us.

ALSO READ: Benefits of Using Push Button Legend Plate

Original Source: https://bit.ly/3s5qlPX

Comments

Post a Comment