Process to Make Metal Name Plates?

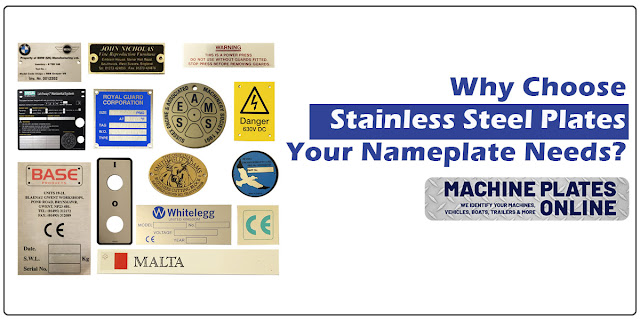

Metal nameplates are a form of labeling commonly uses in commercial, industrial and aesthetic applications. Metal name plates are being used more and more widely in various industries like electronic products, home appliances, machinery and civilian products. Metal signs are mainly made of copper, stainless steel, iron, aluminum, zinc alloy, and lead-tin alloy through stamping, die-casting, etching, printing, enamel, imitation enamel, and baking varnish technologies.

Also Read For How Do Locker Number Plates and Name Tags Work?

1. Design the artwork:

The common software for designing includes Adobe Photoshop, Adobe Illustrator and Corel Draw. If you want to make 3D sign renderings, you need to use 3D Max and related software. Regarding the color system, PANTONE SOLID COATED is usually used, because the PANTONE color system can better match colors and reduce the possibility of color difference.

2. Make a mold:

Remove the color on the artwork, and make a black-and-white manuscript with black and white color representing the concave and convex metal, and print it on a certain ratio of sulfuric acid paper. Use the photosensitive ink to make the engraving template, and then use the engraving machine to engrave the template To perform engraving. After the engraving is completed, the mold needs to be tempered to enhance the hardness of the mold.

3. Suppress:

Install the mold on the punching hydraulic table, and then punch and hydraulic the pattern onto the aluminum and different sign making materials.

4. Punching material:

Use the pre-made knife mold to press the product according to its shape and use a punch to punch the product down.

5. Polishing:

Put the product punched out by the knife die into a polishing machine for polishing, remove the punching burrs, and improve the finish of the product.

6. Electroplating and coloring the signs:

According to customer requirements, the signs can be electroplated, which can be gold-plated, silver-plated, nickel-plated, copper-plated, etc., and then color the signs according to customer requirements, finish the color, and bake at high temperature to enhance the color fastness. Through this step, a complete sign that meets the customer’s requirements is produced.

The best metal nameplate manufacturers can assist in end-to-end nameplate production. Machine Plates Online is one of the best name plate manufacturers and suppliers who offer fast quotes on a variety of sizes that are all durable and long lasting.. As a premier manufacturer of machine identification solutions, we provide custom printed or laser engraved machine plates, labels, metal id plates and nameplates.

ALSO READ FOR

Comments

Post a Comment